Rolling Contact Type Automatic Voltage Controllers Servo Voltage Stabilizers

Capacity : 30 to 8000 KVA

Apaar Electrical’s is known for reliability and continuous improvement in the field of rolling contact type automatic voltage controller, servo voltage controller, automatic voltage stabilizer, chemical process rectifiers, electroplating power rectifiers and special purpose transformers. The systems are designed and supervised by a team of qualified engineers having more than 20 years of experience to achieve best possible quality and total customer's satisfaction.

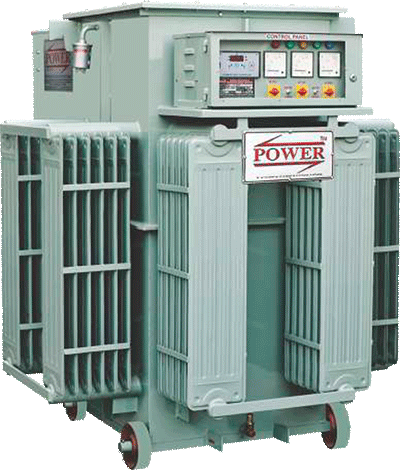

1250 KVA AVR

Rolling Contact Type Automatic Voltage Controller / Servo Voltage Stabilizer Different Types of Automatic Voltage Controller (Customized)

Standard Control Card & Relay Control Circuits

Automatic Voltage Controller (Balance Type) with Special Control Circuit

Automatic Voltage Controller (Unbalance Type + Complete byepass Arrangement)

Automatic Voltage Controller (Balance Type) (Standard Type)

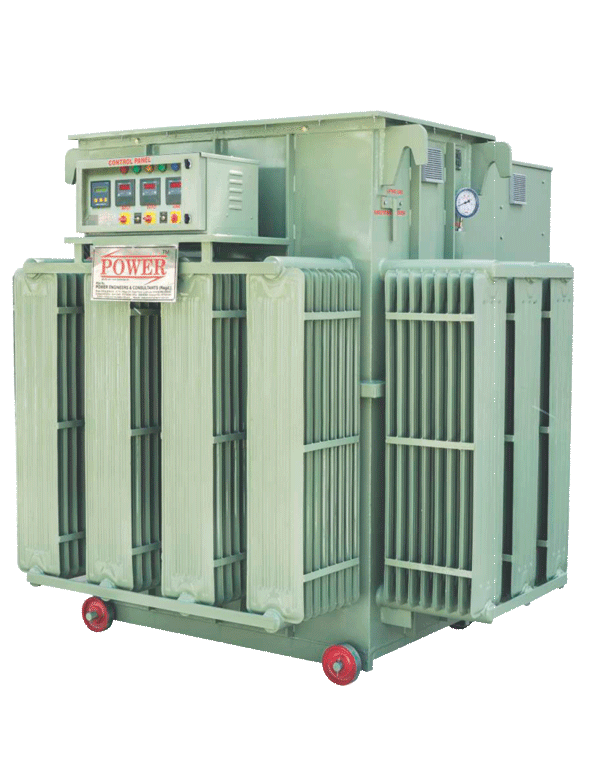

2500 KVA Automatic Voltage Controller

1000 KVA Automatic Voltage Controller (Unbalance Type + Complete byepass Arrangement)

40 KVA Automatic Voltage Controller (Unbalance Type+complete bypass Arrangement standard type)

150 KVA Automatic Voltage Controller (Unbalance Type with Complete byepass Arrangement)

Automatic Voltage Controller (Unbalance Type) (Standard Type)

Description of Automatic Voltage Controller:

Power Servo Stabilizer Primarily Consists of The Following :-

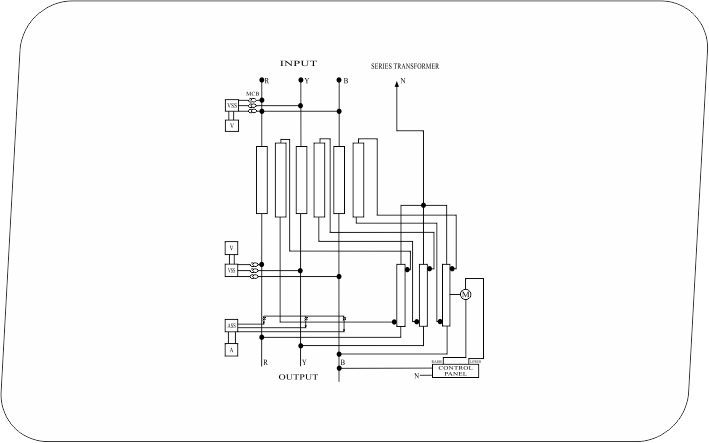

Linear, Plus / Minus Type Vertical Rolling Contact Voltage Regulator:

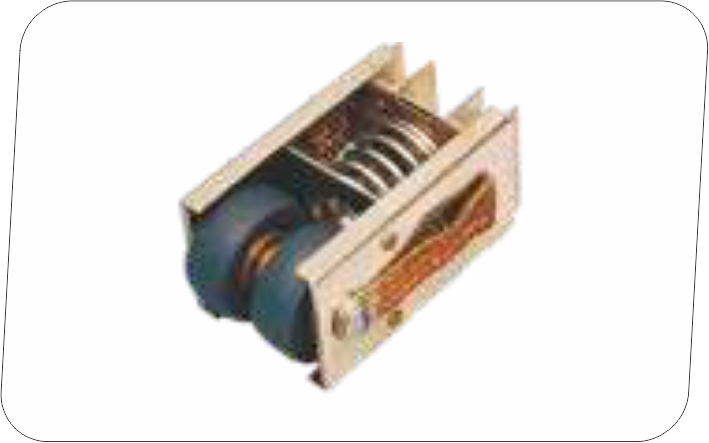

In our regulators, we are using heavy section of electrolytic grade rectangular copper strip instead of copper wire to minimize the losses & increase the efficiency of equipment. We are using self lubricating Carbon Roller Assemblies instead of ordinary Carbon Brushes, which offers more reliability and trouble free performance of the equipment.

Double Wound Buck / Boost Type Series Transformer:

In our Buck/Boost transformers, we are using CRGO lamination to minimize iron losses and coils of Buck / Boost transformer are wound with heavy section of multi strips electrolytic copper to minimize copper losses for getting better efficiency of the equipment.

Electronic Control Circuit and Meter Panel:

Power Automatic Voltage Controller consists of very simple electronic control circuit for monitoring and controlling voltage, repair & maintenance of which is very easy.

The regulator and Buck / Boost transformer are oil cooled, housed in same or separate sheet steel tanks. Radiators are provided for effective cooling. The coils of voltage regulator & Buck / Boost Transformers are vacuum impregnated and oven dried as per IS.

Inner view of automatic voltage controller unbalance type with ultra Isolation Transformer

Inner view of Stabilizer (Balanced Type)

Inner view of Automatic Voltage Controller (Unbalanced Type ) Export

Close View of Regulator

Carbon Roller Assembly

Basic Circuit

Comparison Between Roller Type & Conventional Make Automatic Voltage Controller

ROLLER

TYPE REGULATOR

- Power consumption is 0.5 to 1.5% depending upon the model and input voltage variation.

- Suitable for continuous 100% duty cycle.

- The carbon (graphite) Roller roll, while moving on the coil track, so contact Point of the roller goes on changing which prolongs the life of the rollers.

- Life atfull load is 15-20years.

- Negligible losses in full Buck/Boost Condition.

- Five years of Unconditional warranty in India.

CONVENTIONAL MAKE WITH

CARBON BRUSH REGULATOR

- Power consumption is 2 to 7% depending upon the model and input voltage variation.

- Suitable for only 30% to 40% duty cycle.

- Since the contact is by brush having flat surface, wear & tear of the brush is more and requires frequent replacement.

- Maximum life is 2-3 years at full load.

- Max. Lossesinfull Buck/Boost condition.

- Normalwarranteeforoneyear

Comparison Between Roller Type & Conventional Make Automatic Voltage Controller

| Capacity | Roller Type Regulator Losses | Conventional Make Carbon Brush Type Dimmerstat Losses |

| 60 A | 575 W | 1050 W |

| 75 A | 730 W | 2055 W |

| 100 A | 900 W | 3105 W |

Rolling Contact Type Automatic Voltage Controller / Servo Voltage Stabilizer

Technical Data

Servo Stabilizers are available in a wide range and various models. The standard three phase models are suitable for balanced & unbalanced supply and loads. The standard models conforming to the following specification:

| Input Voltage | 360-450 V | 350-460 V | 340-460 V | 340-480 V | 340-480 V | 300-480 V |

| Efficiency (as per calculation) | 99.3% | 99.1% | 98.90% | 98.90% | 98.07% | 98.30% |

| Output Voltage | 400 V ± 1 %, 3 Phase, 50 Hz or as desired | STANDARD ACCESSORIES | ||||

| Output Voltage Adjustment | ±5% | 1 Voltmeter with Selector Switch for I/P & 0/P | ||||

| Output Voltage Regulation | ± 1% (at no load/full load) | 2 Ammeter with Selector Switch | ||||

| Correction Rate | 10 V -15 V / second (or as per requirement) | 3 MCBs for Control Circuit | ||||

| Temperature Rise (Max.) | 35°C - 40°C above ambient | 4 Lifting Lugs | ||||

| Cooling | Naturally Oil Cooled. | 5 Drain Valve | ||||

| Insulation | Class 'A' | 6 Oil Level Gauge | ||||

| Type | Indoor/Outdoor Type or | 7 Earthing Terminal | ||||

| Mode of Operation | Fully Automatic / Semi Automatic / Manual | 8 Rating Plate | ||||

| Mounting | On Uni-directional Wheels | 9 Junction Box | ||||

| Wave form distortion | Nil | 10 Thermometer Pocket | ||||

| Duty Cycle | 100% Continuous | |||||